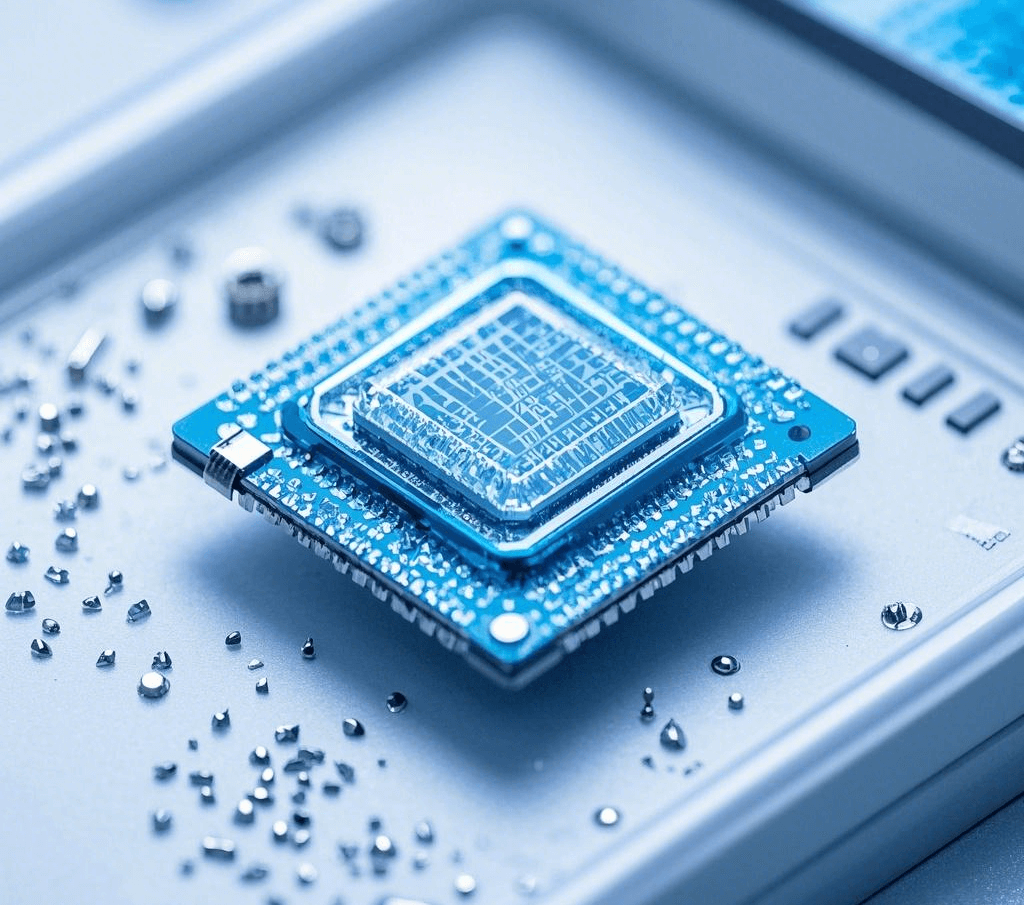

Sensor Manufacturer

Our pressure sensors are engineered to perfection, delivering highly accurate measurements even in the most demanding environments. Whether it’s the high – pressure conditions in industrial pipelines or the delicate pressure variations in laboratory settings, our sensors provide real – time, reliable data.

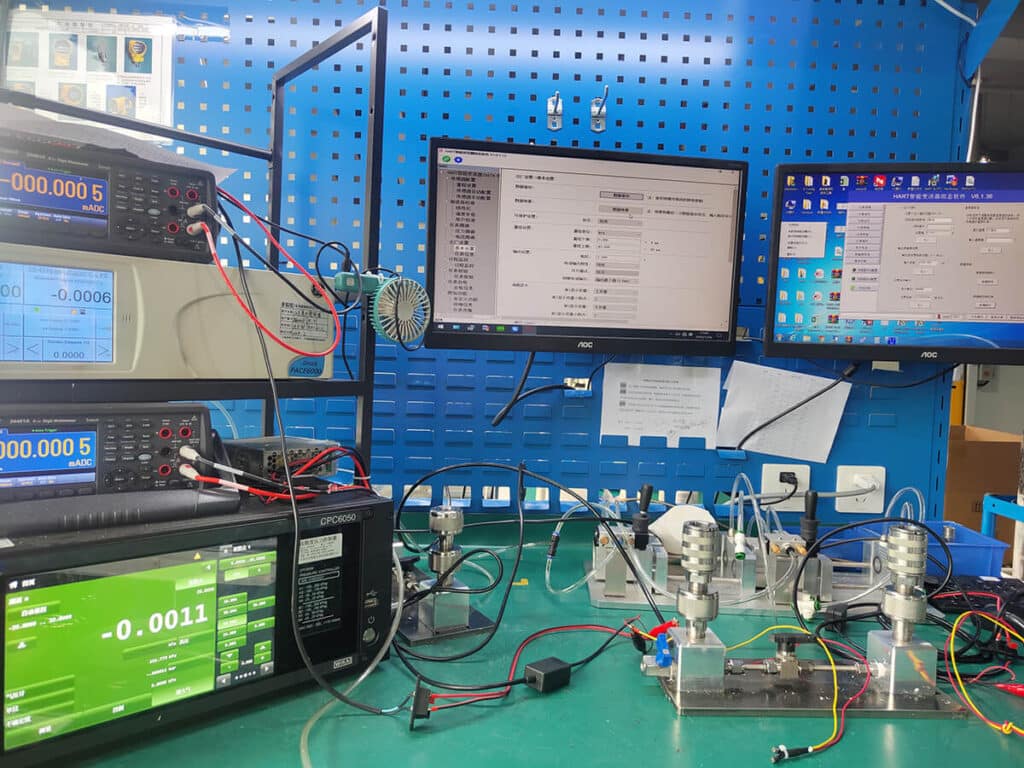

Oil filling technology

In the manufacturing of instruments and meters, our factory’s oil – filling technology is a key process.The oil – filling process is carried out with high precision. Specialized equipment and techniques are employed to ensure an accurate amount of oil is introduced, without any air bubbles or impurities.

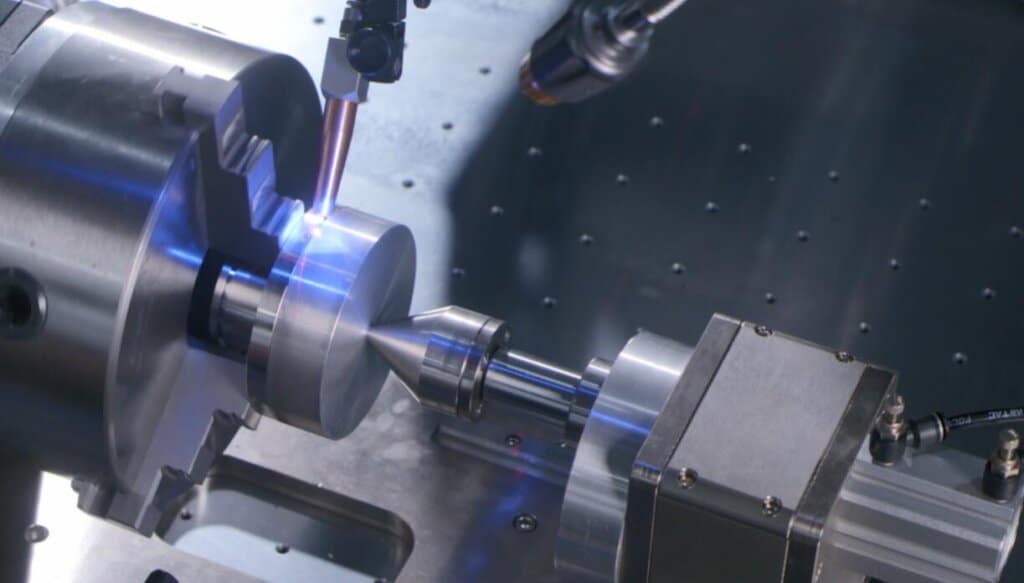

Welding technology

Advanced welding techniques, like laser and TIG welding, are commonly used. Laser welding offers high – energy density, enabling precise and distortion – free joins. TIG welding provides clean, high – quality welds. Skilled welders, with strict quality control, ensure each weld meets industry standards, safeguarding the performance of these sensitive instruments.

Control system solution

Our solutions combine high – performance sensors with intelligent control algorithms. The sensors, a crucial part of our instruments, accurately capture data on various physical parameters such as pressure, temperature, and flow. This data is then processed in real – time by sophisticated control algorithms.

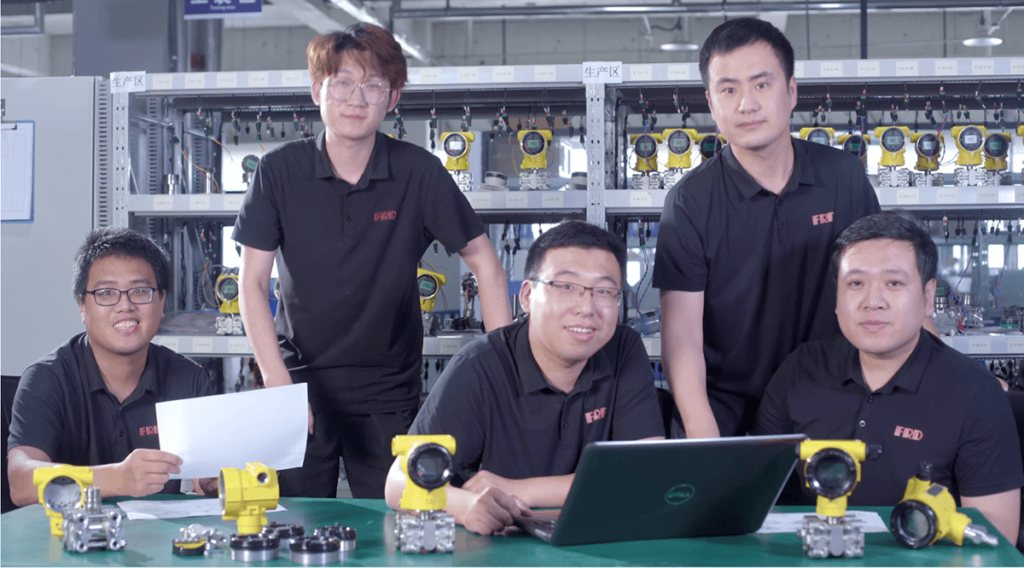

Professional team

With a team of dedicated engineers and a commitment to innovation, we continuously strive to improve our products. We use state – of – the – art manufacturing processes and the highest quality materials to guarantee durability and long – term performance.